Powerful words that shift the business culture, a lesson by Toyota

Every company has their operating system when it comes to building a management philosophy. With culture and strategies working differently for each of us, there’s no denying that Toyota is definitely a leader in their socio-technical system.

The Japanese automotive manufacturer- aside from being the sixth largest company in the world by revenue – is widely known for its production system (TPS-The Toyota Production System). The strategy organizes manufacturing and logistics, including interaction with suppliers and customers. This has resulted in Toyota being widely praised and analyzed for its production and ethical quality.

The TPS approach integrates a pretty exclusive terminology; the terms-often used as principles-offer a new perspective on business interactions, and we’re here to share some chosen favorites.guu

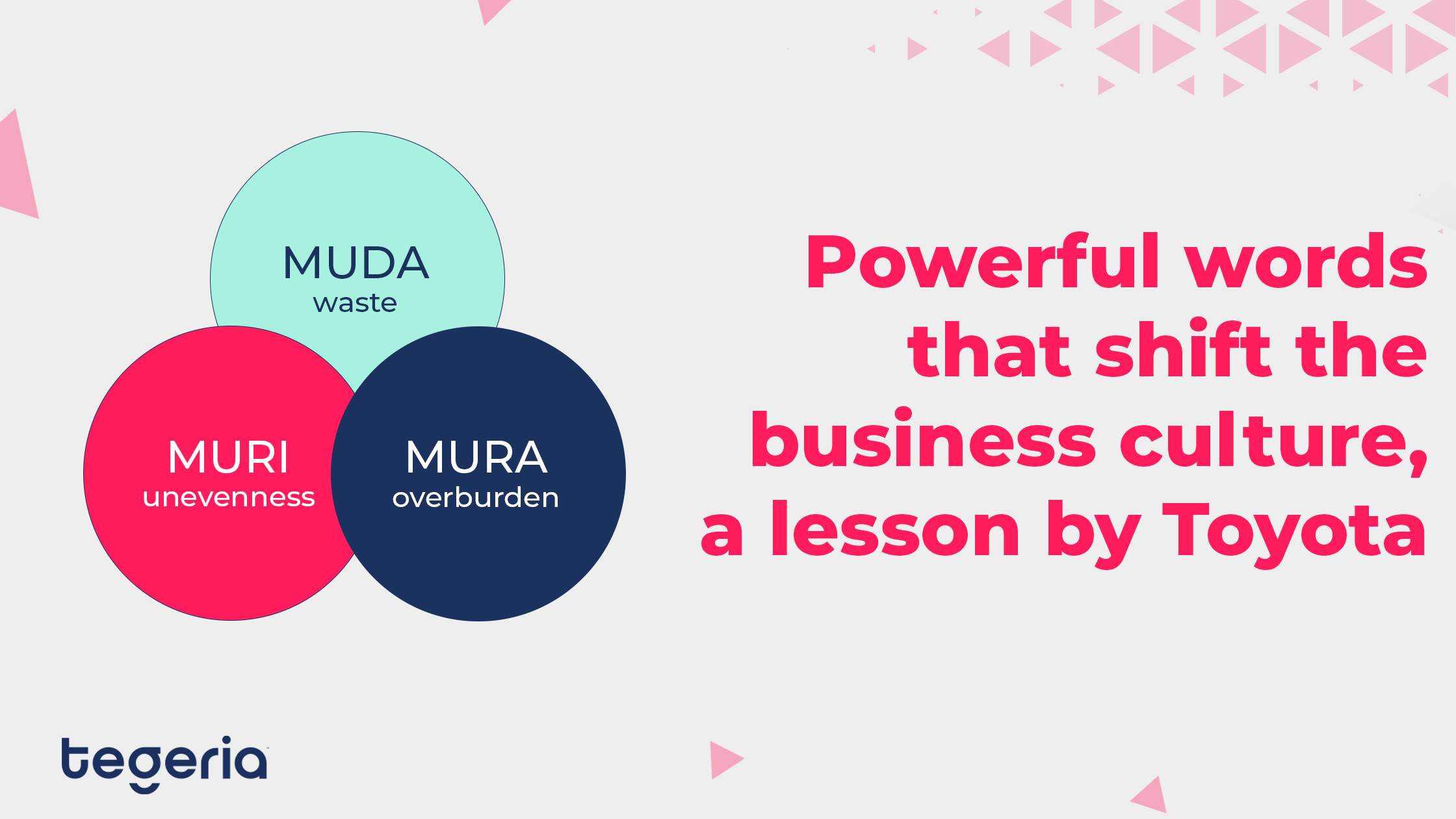

Muda, Mura, Muri – The three evils, 666’s of your business.

These cubic M’s collectively represent wasteful procedures that need eliminating in manufacturing. They deviate from an optimal distribution of resources, as definite enemies of Lean.

Starting with Muda, the most infamous one, it is originally identified as seven forms of waste:

- Transportation

- Movement

- Waiting

- Over-Processing

- Defects and Rework

- Inventory

- Overproduction.

Basically, any activity that consumes resources without creating value for the customer. While most people who have had contact with lean manufacturing are aware of the 7 wastes and Muda, they might disregard Muri and Mura, often not even being aware of them.

Yet these wastes are quite complicated to tackle and sometimes become the underlying causes of the Muda within your processes.

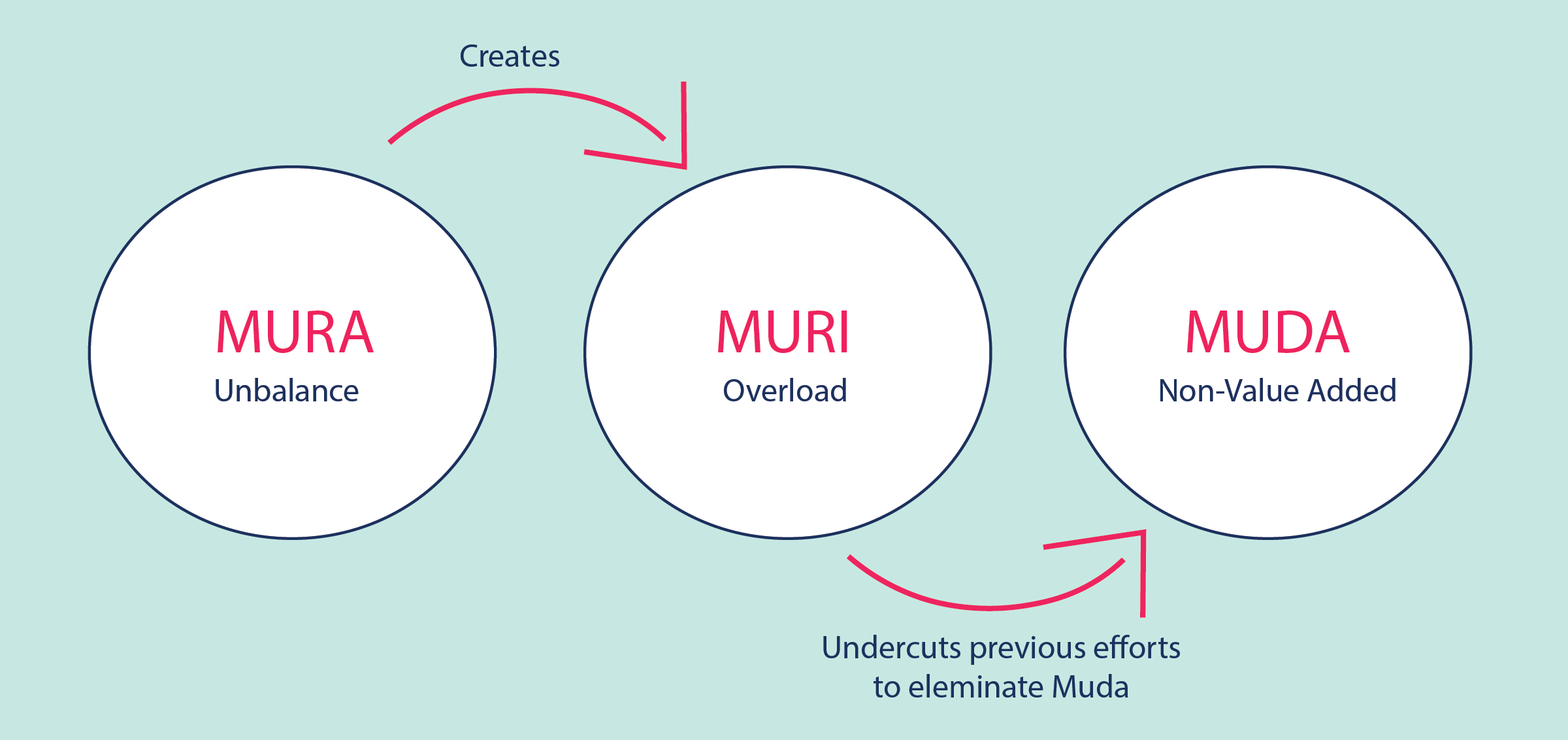

Mura is a type of waste caused by unevenness in production and services, or due to a lack of proper standards. This creates most of the seven wastes, so Mura drives Muda.

Muri (overburden) is the result of tasks or processes that are overly difficult or give unnecessary stress to your employees. For the most part, this is caused when workers lack the proper equipment or training.

But if all three all connected, how do we resolve each?

By focusing on solving Mura and Muri you prevent the creation of Muda.

First, you make sure your Mura (unevenness) is removed, thereby creating a balanced and smooth production level; this, in turn, highlights the Muri (overburden) within your system which can then be eliminated.

These actions will definitely result in the decrease of the Muda in your business.

Genchi Genbutsu-“Go and See”

Going beyond just looking at the problems from afar, and instead seeing the source of them yourself at the gemba (real; actual place), is the foundation behind this principle.

If something isn’t working correctly, “get ya boots” on and examine what is going on in order to achieve high effectiveness.

This management presence is something we at Tegeria like to implement as well because second-hand information doesn’t always add value to your problem-solving concerns.

The mirror of your mistakes, Hansei.

Hansei, also known as self-reflection, means to recognize mistakes and take appropriate action to avoid recurrence.

Modesty and humility are key components when analyzing in a critical and objective manner. But that doesn’t mean that they are easy to apply.

However, when you work as a team, you take individual failures and successes together, by identifying experiences and putting more effort into the future.